Company Brochure

Download our company brochure and learn how our product can help you solve Your water challenges

PRODUCTS

Learn about our range of membranes & modules

we have supplied our membranes for a treatment capacity in excess of:

560.000.000 liters/day

70% Drinking water

20% Industrial wastewater

10% Municipal wastewater

>260 commercial installations

>65 countries

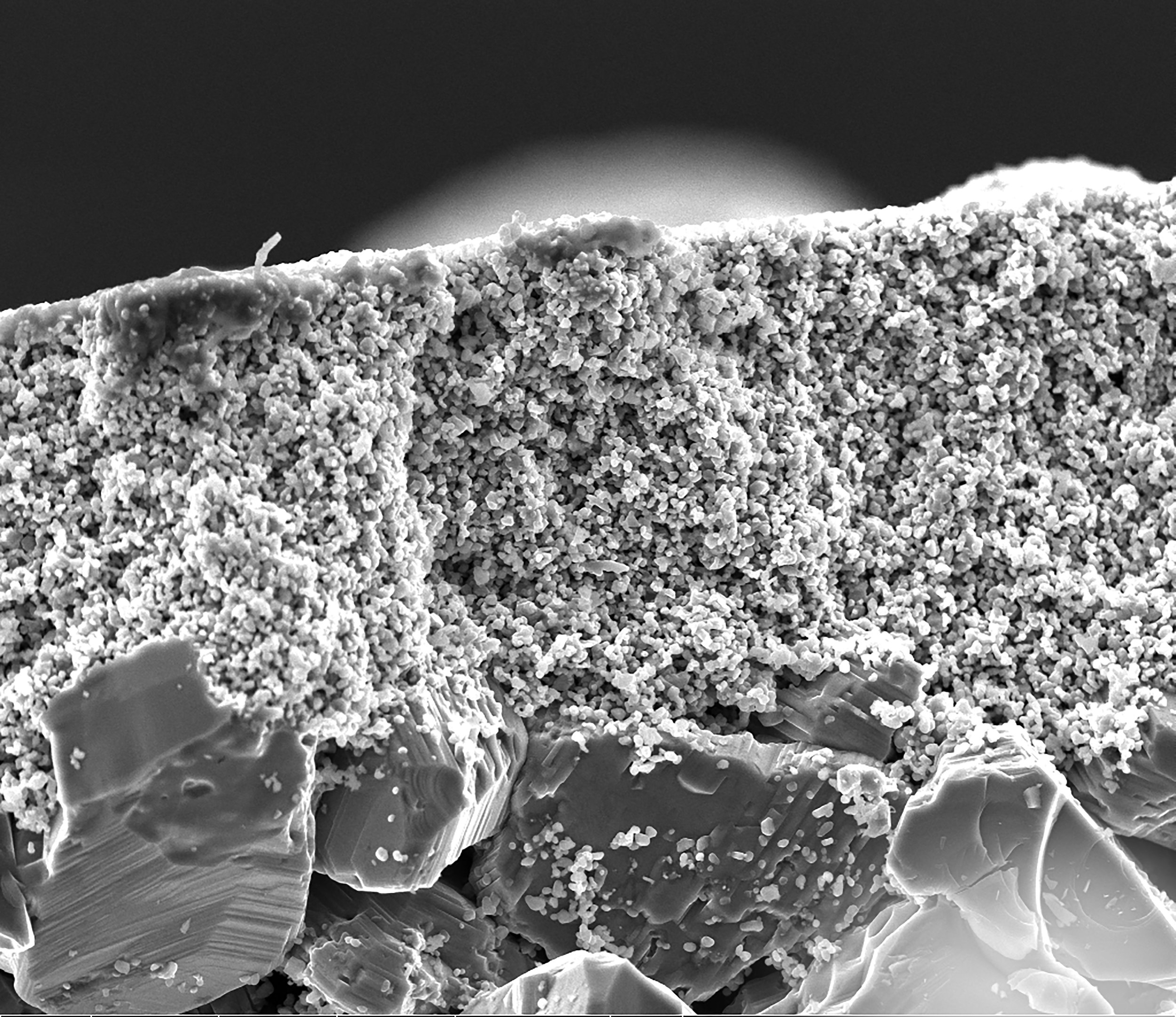

TECHNOLOGY

Learn more about our proprietary Silicon Carbide (SiC) membrane technology

L E A R N A B O U T S O M E O F O U R

REFERENCES

APPLICATIONS

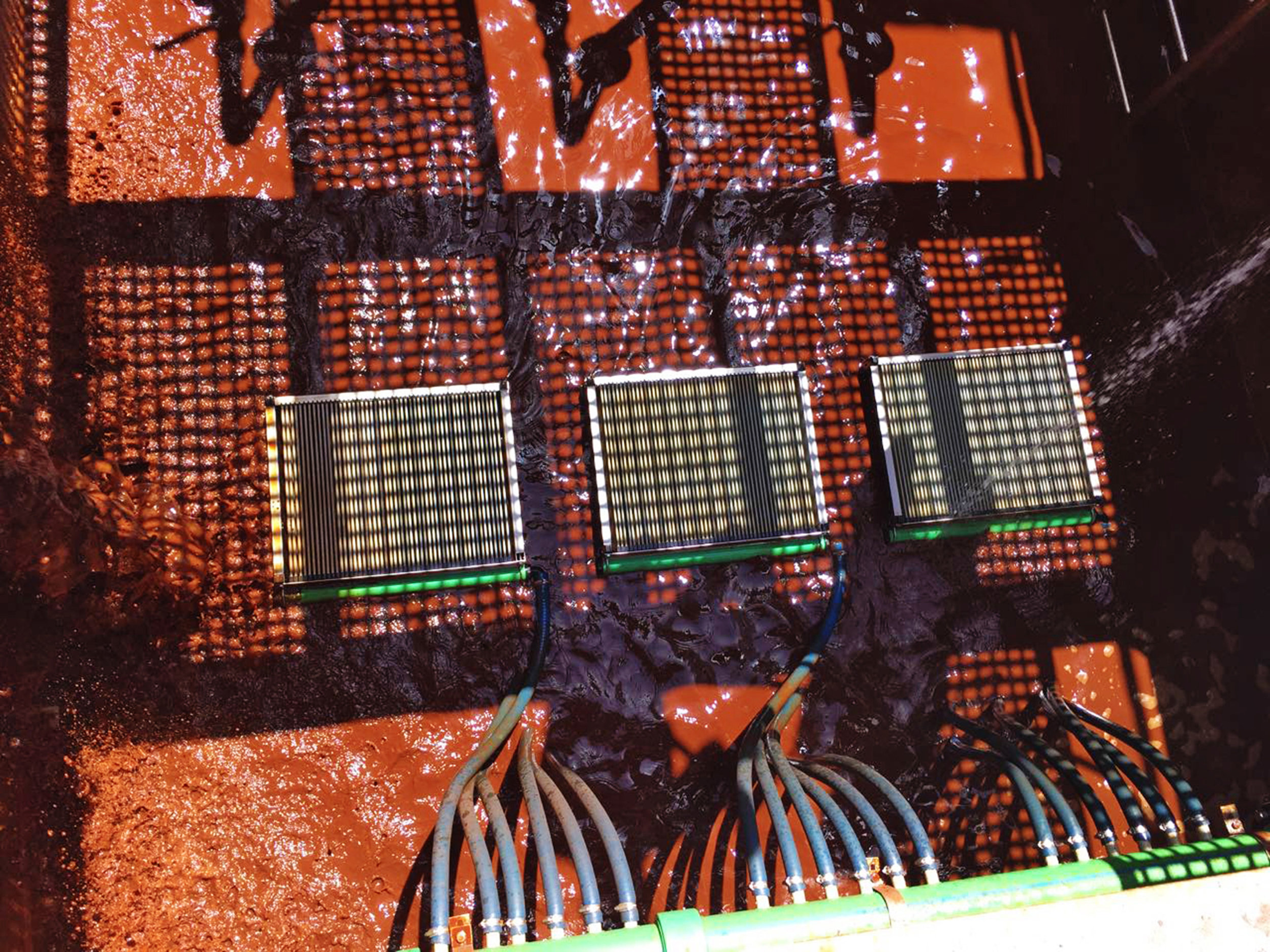

MBR

DRINKING WATER

MUNICIPAL & INDUSTRIAL WASTEWATER

GRAVITY MEDIA FILTER UPGRADES

SCRUBBER WASTEWATER

PRODUCED WATER

STORM WATER

PRE- & POST RO TREATMENT

T A K E A P E A K I N T O O U R

FACILITY

L A T E S T C E M B R A N E

NEWS

T E A M C E M B R A N E

Cembrane mission is to enable more widespread reuse of wastewater & to provide safer drinking water everywhere.

By pushing the boundaries of flux rate, durability, & cost-effective water treatment through innovation within SiC membrane technology.